Description

Product Introduction

Product Introduction

Introduction

As a leading manufacturer of Galvanized Flange Nut located in China, we are committed to serving our customers with high-quality and durable products. Our nuts are made from premium materials to meet the highest standards of quality and safety. Our mission is to offer a reliable and long-lasting solution for your needs. In this article, we will be sharing the features and benefits of our Galvanized Flange Nut to help you understand why it's the best choice for your business.

Features of our Galvanized Flange Nut

1. Material

Our Galvanized Flange Nut is made using high-quality materials that are corrosion-resistant, meaning the nut will not rust easily. It is made from steel, a material that is known for its strength, durability, and malleability.

2. Galvanized finish

Galvanization is the process of coating metals with zinc to protect them against rust and other forms of corrosion. Our Galvanized Flange Nut is coated with a layer of zinc to prevent rusting and ensure longevity. The zinc layer also gives the nut a shiny and attractive appearance.

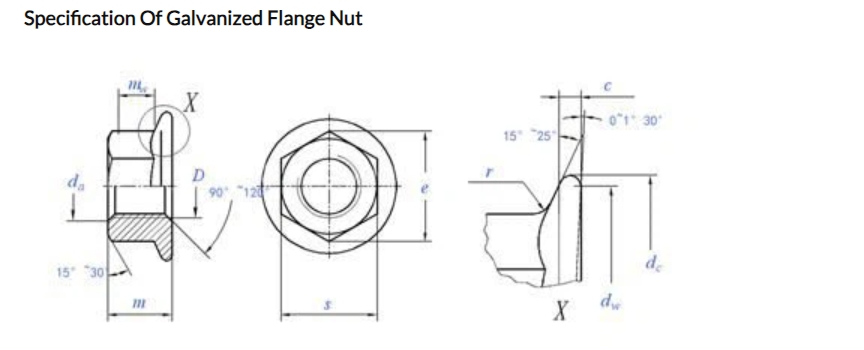

3. Flange design

Our Galvanized Flange Nut has a flange design that provides extra surface area for even distribution of pressure. This design ensures that the nut stays securely in place, providing a reliable and sturdy solution for your application.

Benefits of our Galvanized Flange Nut

1. Corrosion resistance

Our Galvanized Flange Nut is designed to resist corrosion and rusting. This makes it suitable for use in harsh environments such as marine, industrial, and automotive applications. The galvanized finish ensures that the nut can withstand exposure to moisture, saltwater, and other chemicals.

2. Easy to install

Our Galvanized Flange Nut is easy to install due to its flange design. The flange provides a large surface area for added stability, making it easier to install and remove. This can save you time and money in labor costs, as well as reduce the likelihood of damage to your equipment.

3. Long-lasting

Our Galvanized Flange Nut is built to last. The high-quality steel material and galvanized finish make it durable and capable of withstanding extreme weather conditions, high pressure, and heavy loads. This ensures that your equipment stays in good working condition for longer, reducing the need for frequent repairs or replacements.

4. Versatile

Our Galvanized Flange Nut is suitable for use in a variety of applications, including construction, automotive, marine, and industrial. It is a versatile product that can be used in place of standard nuts, providing added stability and reliability. The flange design also makes it suitable for use with bolts of varying lengths.

Conclusion

In conclusion, our Galvanized Flange Nut is a high-quality, durable, and corrosion-resistant product that is ideal for use in a wide range of applications. Its flange design provides added stability and reliability, making it an excellent choice for use in harsh environments where other nuts would fail. Our commitment to quality ensures that you will receive a top-performing product that is built to last. If you have any questions or would like to place an order, please don't hesitate to contact us.

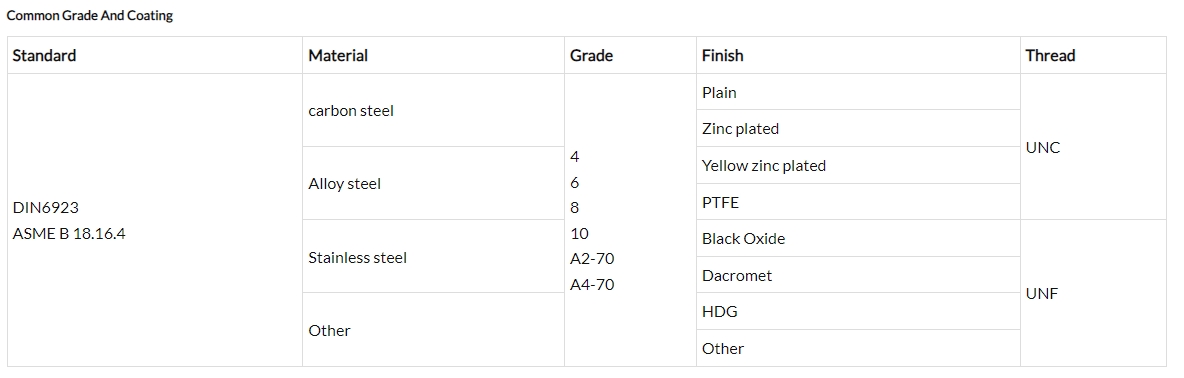

The surface treatment of DIN6923 flange nuts is generally divided into two types: yellow zinc and zinc plated, they are cold-galvanized. For hot dip galvanizing, hex flange nut is inappropriate. This is because the residual zinc sticking to the thread after hot-dip galvanizing is not easy to remove, and the thickness of the zinc layer is uneven, which affects the fit of the parts.In addition, the high operating temperature of hot-dip galvanizing will reduce the mechanical strength of grade 8 10 flange nuts .

Due to the above limitations, and DIN6923 flange nuts have small sizes, irregular shapes, and some need to be threaded, hot-dip galvanizing is not suitable for hex flange nuts.

Advantages Of Galvanized Flange Nut

1. Low processing cost: the cost of galvanizing is lower than that of other coatings;

2. Durable and good anti-corrosion performance.

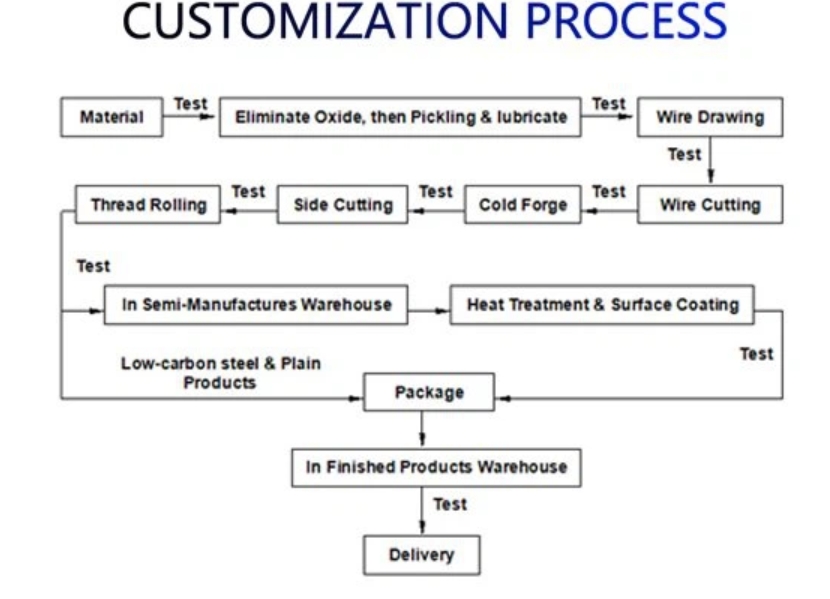

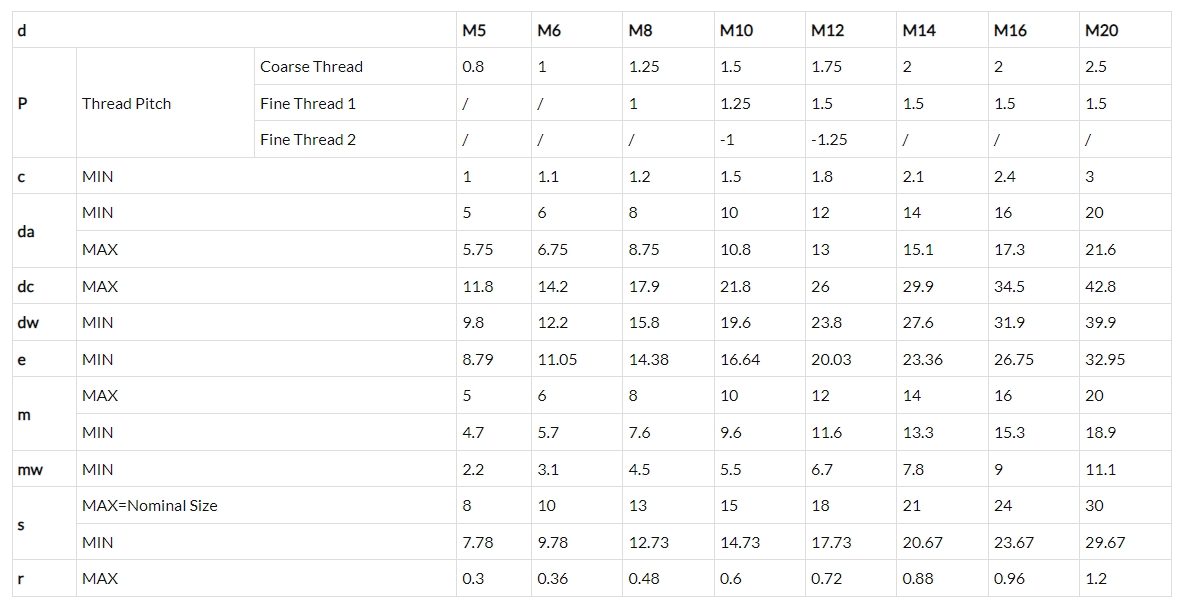

Production Process Of Hex Flange Nuts

Product Introduction

Introduction

As a leading manufacturer of Galvanized Flange Nut located in China, we are committed to serving our customers with high-quality and durable products. Our nuts are made from premium materials to meet the highest standards of quality and safety. Our mission is to offer a reliable and long-lasting solution for your needs. In this article, we will be sharing the features and benefits of our Galvanized Flange Nut to help you understand why it's the best choice for your business.

Features of our Galvanized Flange Nut

1. Material

Our Galvanized Flange Nut is made using high-quality materials that are corrosion-resistant, meaning the nut will not rust easily. It is made from steel, a material that is known for its strength, durability, and malleability.

2. Galvanized finish

Galvanization is the process of coating metals with zinc to protect them against rust and other forms of corrosion. Our Galvanized Flange Nut is coated with a layer of zinc to prevent rusting and ensure longevity. The zinc layer also gives the nut a shiny and attractive appearance.

3. Flange design

Our Galvanized Flange Nut has a flange design that provides extra surface area for even distribution of pressure. This design ensures that the nut stays securely in place, providing a reliable and sturdy solution for your application.

Benefits of our Galvanized Flange Nut

1. Corrosion resistance

Our Galvanized Flange Nut is designed to resist corrosion and rusting. This makes it suitable for use in harsh environments such as marine, industrial, and automotive applications. The galvanized finish ensures that the nut can withstand exposure to moisture, saltwater, and other chemicals.

2. Easy to install

Our Galvanized Flange Nut is easy to install due to its flange design. The flange provides a large surface area for added stability, making it easier to install and remove. This can save you time and money in labor costs, as well as reduce the likelihood of damage to your equipment.

3. Long-lasting

Our Galvanized Flange Nut is built to last. The high-quality steel material and galvanized finish make it durable and capable of withstanding extreme weather conditions, high pressure, and heavy loads. This ensures that your equipment stays in good working condition for longer, reducing the need for frequent repairs or replacements.

4. Versatile

Our Galvanized Flange Nut is suitable for use in a variety of applications, including construction, automotive, marine, and industrial. It is a versatile product that can be used in place of standard nuts, providing added stability and reliability. The flange design also makes it suitable for use with bolts of varying lengths.

Conclusion

In conclusion, our Galvanized Flange Nut is a high-quality, durable, and corrosion-resistant product that is ideal for use in a wide range of applications. Its flange design provides added stability and reliability, making it an excellent choice for use in harsh environments where other nuts would fail. Our commitment to quality ensures that you will receive a top-performing product that is built to last. If you have any questions or would like to place an order, please don't hesitate to contact us.

The surface treatment of DIN6923 flange nuts is generally divided into two types: yellow zinc and zinc plated, they are cold-galvanized. For hot dip galvanizing, hex flange nut is inappropriate. This is because the residual zinc sticking to the thread after hot-dip galvanizing is not easy to remove, and the thickness of the zinc layer is uneven, which affects the fit of the parts.In addition, the high operating temperature of hot-dip galvanizing will reduce the mechanical strength of grade 8 10 flange nuts .

Due to the above limitations, and DIN6923 flange nuts have small sizes, irregular shapes, and some need to be threaded, hot-dip galvanizing is not suitable for hex flange nuts.

Advantages Of Galvanized Flange Nut

1. Low processing cost: the cost of galvanizing is lower than that of other coatings;

2. Durable and good anti-corrosion performance.

Production Process Of Hex Flange Nuts

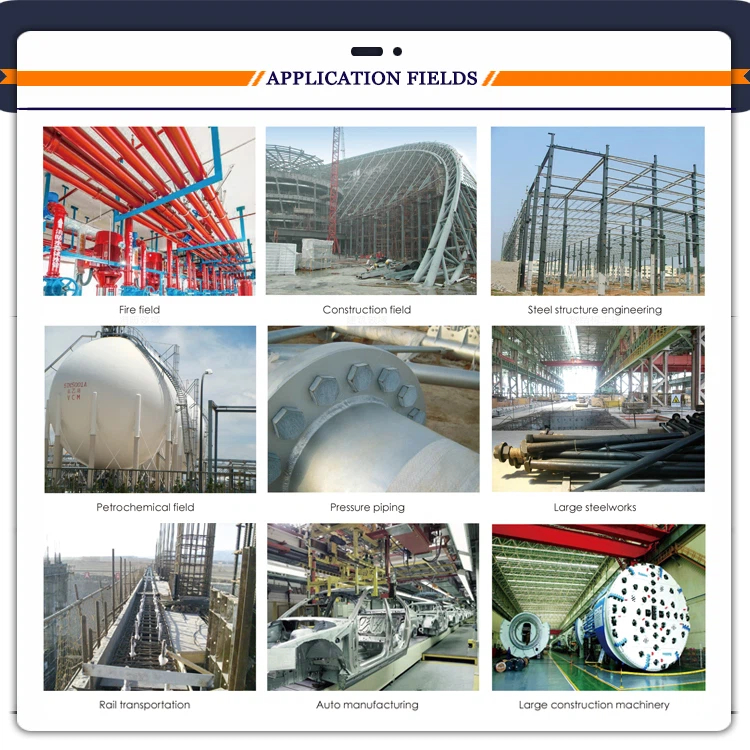

Application Area Of Hex Flange Nuts

Because the flange nut has a flange, it has the effect of increasing the contact area with the workpiece of the product. It is mostly used in pipe connections, scaffolding fasteners, and some metal stamping parts and cast iron parts that need to increase the contact surface of the nut. If you are not clear about your usage scenario, you can consult our customer service. As a professional machine screw manufacturer, we can provide you with reasonable suggestions.