Description

Product Introduction

Double End Studs are an essential component in the manufacturing and construction industry, making them a must-have for those seeking premium quality and reliable fastening solutions. Our company, based in China, has been a leading supplier of Double End Studs for various industries for over a decade. We specialize in manufacturing, wholesaling, and exporting high-quality studs to customers in different parts of the world.

Our Double End Studs are versatile and can be used in a variety of applications, including engineering, production, and assembly. They are made from top-quality materials, ensuring durability and reliability. We have strict quality control measures in place at each stage of production to ensure that we deliver only the best products to our customers.

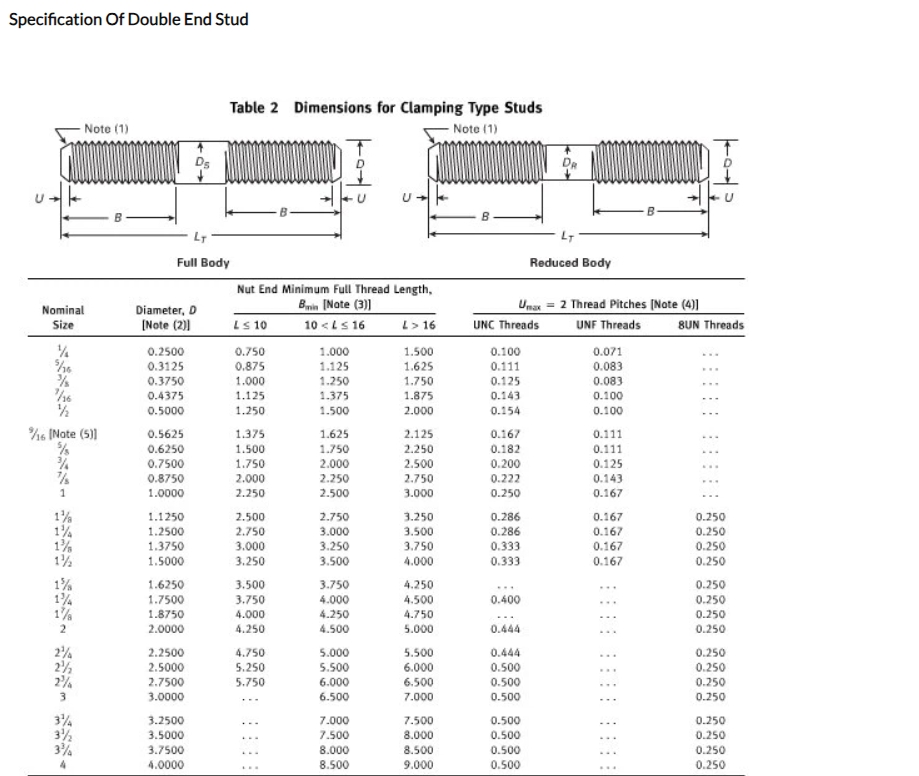

Our range of Double End Studs come in various sizes, materials, and finishes, which makes them suitable for a wide range of applications. Our studs come in different thread sizes, pitches, lengths, and diameters, with common materials including stainless steel, aluminum, and brass. We also offer a wide range of finishes, such as zinc coating, black oxide coating, and electroplating, among others. With such a wide variety of choices, our customers can select a Double End Stud that perfectly meets their exact requirements.

Our Double End Studs have unique features that have earned us a reputation for excellence in the industry. Some of these features include:

1. High Tensile Strength: Our Double End Studs undergo rigorous stress tests to ensure that they can handle extreme pressure, loads, and vibrations.

2. Easy Installation: The Double End Studs come with a double threaded end, making them easy to install and remove.

3. Resistant to Corrosion: Our Double End Studs are designed to resist rusting and corrosion, making them ideal for use in harsh environments like marine or industrial facilities.

4. Precision Design: Our products are designed with precision and 100% accurate tolerances, ensuring that all screw-in components connect without looseness or play.

5. Affordability: Though our Double End Studs are made of premium materials and come with a wide range of features, we have maintained their affordability. We offer competitive prices, without compromising on quality.

In addition to the quality of the product itself, we are also dedicated to providing top-notch customer service. We have a team of experienced sales representatives that is well-trained and knowledgeable in all aspects of our products. Our friendly and responsive customer service ensures that our customers get all the information they need to select the right Double End Studs for their application. Our after-sales service is equally exceptional, ensuring any concerns or complaints are handled efficiently and in a timely manner.

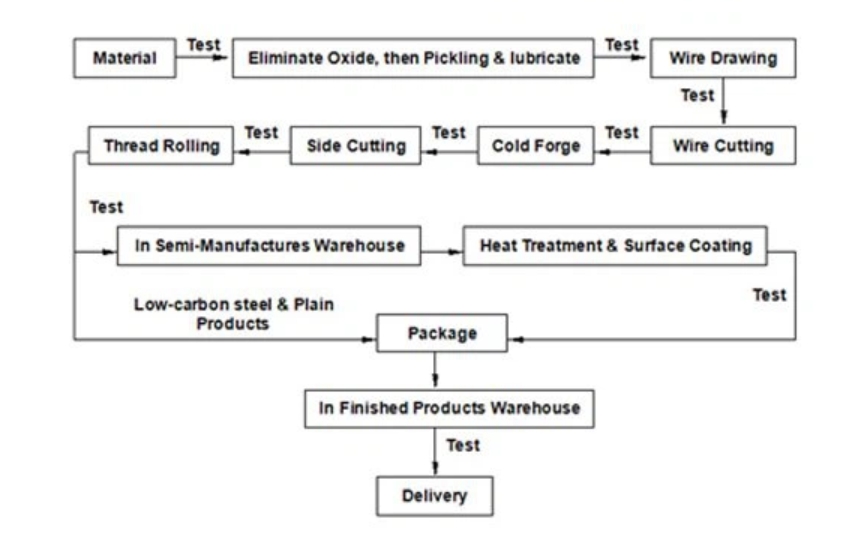

At our manufacturing facility, we use the latest technologies and equipment to ensure that each Double End Stud meets the highest standards of precision and quality. Our team of engineers continuously analyzes and optimizes our production processes to maintain the highest possible standards. We maintain appropriate inventory levels, ensuring that we can fulfill orders quickly and efficiently.

In conclusion, our Double End Studs are the top choice for engineers, manufacturers, and constructors who value quality, reliability, and durability. With a wide range of sizes, materials, and finishes, we have a Double End Stud to suit the needs of any application. Our high-quality products, competitive pricing, exceptional customer service, and state-of-the-art manufacturing facility, make us the go-to supplier for top-quality Double End Studs in China and beyond.

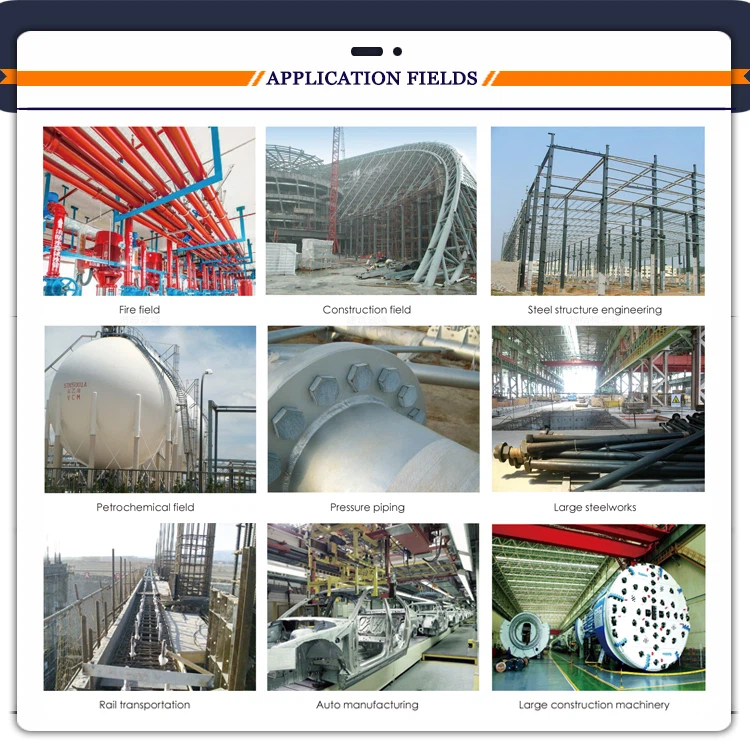

Double-headed studs are cylindrical fasteners with threads at both ends of the index finger. They are widely used in electric power, chemical industry, oil refining, valves, railways, bridges, steel structures, automobile and motorcycle accessories, machinery, boiler steel structures, hanging towers, large-span Steel structures and large buildings, etc.

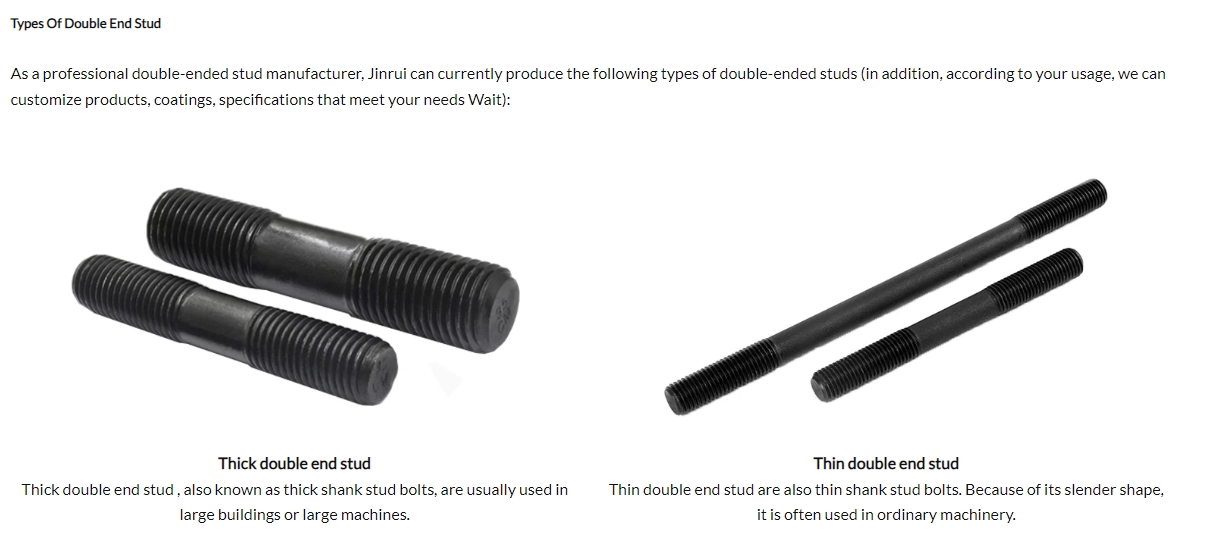

A double-ended stud is a stud with threads at both ends, and a section of stud without threads in the middle. According to the usage scenario, the threads at both ends can be in the same direction or in the opposite direction, and the lengths of the threads at both ends can be equal or unequal. , The thickness of the screw is also different. double end stud can also be called double end bolt, double end screw, etc., but many times we are used to calling double end stud with larger sizes double end bolt, while double end stud with smaller sizes are called double end screw.

Feature and Advantage

Double end stud fasteners are usually used in large equipment and are suitable for large machinery and accessories to be installed, such as sight glasses, mechanical seal seats, reduction gear racks, etc. The double-ended studs are easy to replace, of good quality, rarely worn or damaged, and can realize the function of free disassembly. In addition, the installation of the double-ended stud is relatively simple, just screw one end into the main body, then install the accessories, and finally screw the nut to the other end to complete the installation.

Application Area Of Double End Stud

Studs are mainly used when the main body is large-scale equipment, and accessories need to be installed, such as sight glass, mechanical seal seat, deceleration rack, etc. At this time, the studs used are screwed into the main body at one end, and the other end is installed after the accessories are installed. With nuts, since the accessories are often disassembled, when the main body and accessories are directly connected by bolts, the main body thread will be worn or damaged over time, and it is very convenient to use stud bolts to replace. And when the thickness of the connecting body is very large and the bolt length is very long, stud bolts are also used. We are a professional stud manufacturer, if you have any questions during use, please feel free to consult us.

How To Buy Double End Stud From Us?

Inquiry

There are two types of fasteners. One is standard parts, such as DIN975, fully threaded stud. The other is non-standard parts. If you want standard pieces, you can tell the standard, size, grade (material), coating and quantity. For example, you want to buy DIN975, M10, grade 8.8, zinc plated and 20000pcs. If you want non-standard parts, you can show us samples, drawings or detailed instructions. Then our engineers will make technical drawings for you.

Price and payemnt